Printing: Bridges

In previous exercises we explained that classic FDM printers cannot print into thin air for physical reasons and thus it’s necessary to have either the print bed or an already printed part of the object under the currently printed part. We showed how to add supports for parts of the model that would require printing into empty space.

However, not all situations require wasting material on printing supports. If you examined what the infill looks like and what happens after printing the infill, you surely noticed that sometimes printing into thin air does occur. If we have 15% infill and want to cover it from above, then logically we’re printing into thin air 85% of the time. How can this work?

Varování:

Follow all safety rules from the previous exercise. Especially don’t stab anyone with a screwdriver and don’t drink chemical cleaning agents.

Bridges

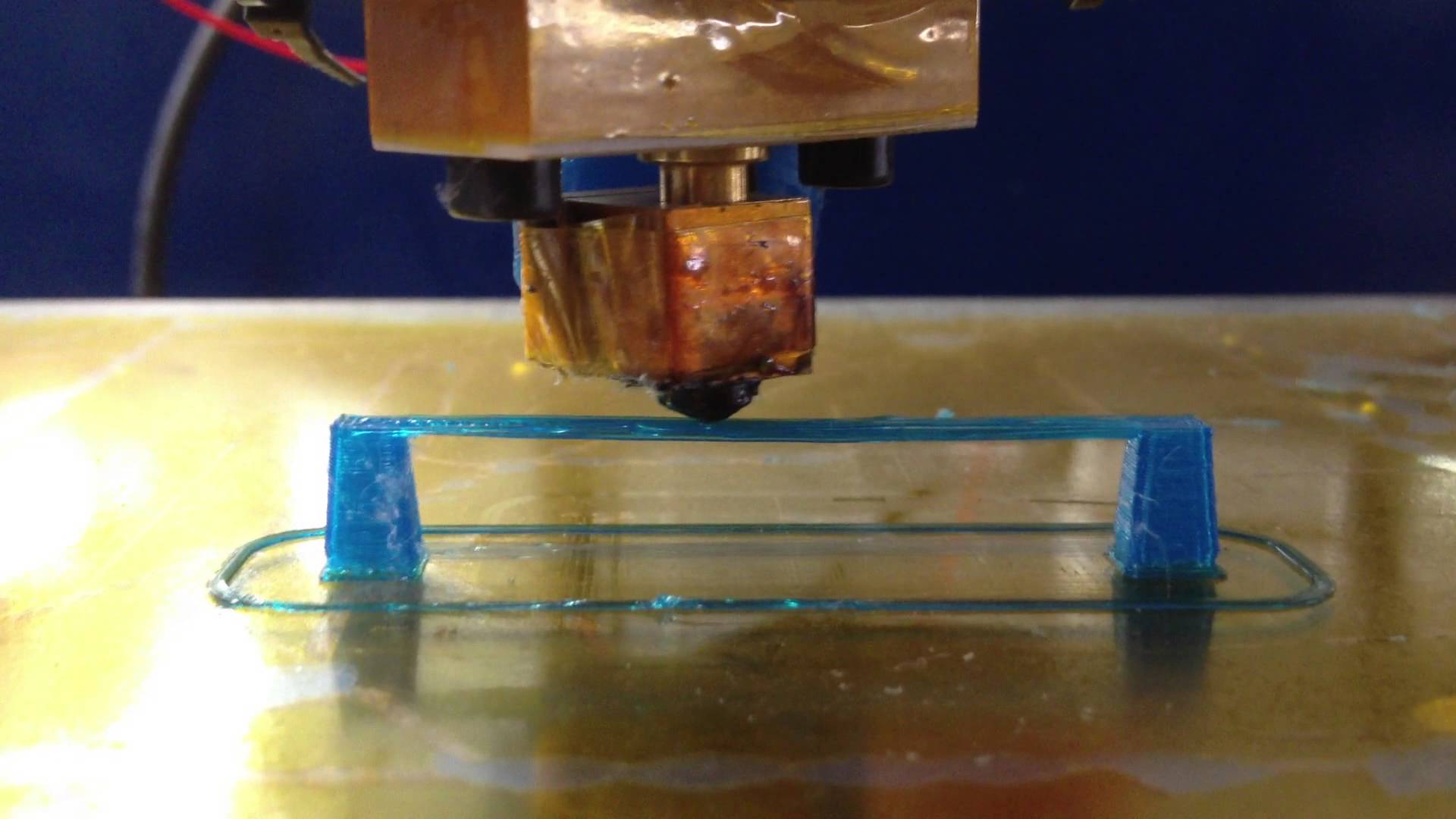

A situation where we print from one fixed point to another ("from shore to shore") with a fast simple linear "stroke" is called bridging.

During bridging we rely on the fact that the plastic filament still flows out of the nozzle (it "hangs") and during the time that the filament holds onto the nozzle, the nozzle manages to move to the second fixed point (to the "opposite shore"), where the filament attaches. The solidification and shrinking of the plastic then ensures that the given filament is taut and straight.

The fan, nozzle movement speed, and amount of extruded plastic play a big role in printing bridges. If the speed is too low, the filament will sag down or fall off the nozzle. High speed can break the filament before it reaches the second point. By blowing on some types of materials (PLA, PET) we can speed up the cooling process.

Logically, it’s not desirable for the bridge to be sagging or have broken filaments.

Bridge Settings in Slic3r

For bridge calibration, values are adjusted in the Slic3r application in the sections:

- Print Settings → Speed → Bridges

- Print Settings → Advanced → Flow

- Filament Settings → Cooling

Důležité:

For today’s exercise, download the config bundle designed for printing bridges and use the settings Bridges, PET_Bridges, Hybrix.

Assignment

During the terraforming of Mars, mission command has assigned you the task of printing a bridge on a 3D printer. At our base we have a scaled-down copy of a 3D printer, which will later print real bridges on Mars.

Each bridge has its own rating. The more valuable the bridge you manage to print, the faster we can terraform Mars. However, the bridge rating is not equally distributed in terms of its height/width. A bridge 20 wide and 30 long is not rated the same as a bridge 30 wide and 20 long. Longer bridges are more valuable. In other words, for points it pays to make bridges longer rather than wider.

Use the file bridge.scad as a bridge generator and generate bridges in OpenSCAD (modifying the module implementation to get more points is considered cheating). Units are in millimeters and this is only the size of the bridge without the size of the pillars. Don’t try to undercut the pillars, it would negatively affect printing properties.

Don’t forget to use the config bundle designed for printing bridges (note, this is a different config bundle than we used last time).

Otherwise, follow the instructions printing step by step.

The bridge rating is always visible on its top side.

Varování:

Check that the pillars are not solid, but have infill. In settings, possibly reduce the value of Solid infill threshold area. Two perimeters will be enough.

Grading

- 1 point for printing a really ugly sagging bridge

- 2 points for printing an ugly bridge

- 3 points for printing a nice bridge

The above points are not cumulative. Those who don’t clean up after themselves don’t get any points. Graded bridges must be at least 30 mm long and have a rating of at least 300.

Bonus

The student pair that manages to print the most valuable bridge will be awarded 3 bonus points. The second best pair gets 2 points and the third best pair gets 1 point.

This competition runs across all parallel sessions. Intermediate results are not communicated to competitors. Only bridges for which you received points above enter the competition. So it’s not possible to, for example, submit a nice short bridge for 3 points and at the same time compete with a really ugly sagging bridge.

Bridges from ABS

If you want, you can also try printing bridges from ABS non-competitively. ABS has greater thermal expansion and is harder to blow on. The bridge pillars have a greater tendency to detach from the bed during printing. If you’re otherwise done and want to print from ABS, ask the instructors for details.