Slicing

A 3D printer is ultimately quite a simple device. It doesn’t work as a box to which we send a 3D model in any format and plastic starts flowing from the printer in the shape of the given 3D model. For printing, we need to send precise print data to the printer.

It works similarly as with 2D printers; we also don’t send .pdf or .tex documents directly to the printer, but they must be converted to PostScript. 2D printers are, however, somewhat smarter than 3D printers, since they only need that PostScript data, not direct instructions when and where the printer should move the print head or advance the roller.

Print data for 3D printers are thus precise instructions when, from where, to where, and how fast the printer nozzle should move and at what moment and how much plastic to extrude. The printer listens to these commands and "stupidly" executes them (except for exceptions – some firmwares perform optimization) regardless of whether the printer has any idea what it’s actually printing. We provide such information in the GCode format.

Print data must be prepared for the printer, and it’s a non-trivial task. Successful data preparation defines how successful the print result will be. Many factors are at play that need to be set – speeds, temperatures, correct movements, printing structures that aren’t part of the 3D model, etc.

GCode

GCode is a text file, relatively human-readable (it describes points in space, though, which are hard to imagine from numbers), but primarily intended for machine processing.

GCode existed before 3D printers (the first implementation appeared in the 1950s) and was used for CNC machines (a 3D printer is also by definition a CNC machine). For the purposes of 3D printing, specific codes are added to GCode (starting with M) that define control of functions intended for 3D printing (nozzle temperature, plastic extrusion).

Each line represents an instruction. It’s described by a code stated first (e.g., G1) followed by named arguments by letter (some instructions have no arguments, some arguments are optional) separated by space (e.g., E4.00000 F3000.00000).

...

M900 K200

G21

G90

M83

G1 Z0.200 F10800.000

G1 E-4.00000 F4800.00000

G1 Z0.800 F10800.000

G1 X83.160 Y86.215

G1 Z0.200

G1 E4.00000 F3000.00000

M204 S1000

G1 F1800

G1 X83.537 Y85.576 E0.03743

G1 X83.991 Y85.070 E0.03433

G1 X107.449 Y63.321 E1.61475

G1 X108.199 Y62.760 E0.04729

G1 X108.903 Y62.398 E0.03996

G1 X109.644 Y62.175 E0.03905

G1 X110.427 Y62.102 E0.03971

G1 X142.209 Y63.237 E1.60533

G1 X143.311 Y63.369 E0.05600

...Tools for Creating GCode

Generating the above-described GCode by hand would not only be impractical, but for more complex models, for the average mortal impossible. Programs called slicers help us create print data. Their name is derived from the word "slice" (in translation "slice"). Because printing is done in layers, the input to these programs is some 3D model and the output is a (sliced) 3D model intended for printing. This is why this process is called "slicing" ("slicing").

There are many slicers; some are better, others worse, some have good UI but don’t do such good work, others are excellent slicers but have terrible UI. You can also find those that have both. A slicer can be standalone software or integrated in some larger whole (e.g., in control software for a 3D printer).

In the BI-3DT course we’ll use the program Slic3r. It ranks among the most commonly used, is open-source software, and the quality of output is sufficiently good.

Slic3r

Slic3r has been developed since 2011 by the community around the RepRap project. It’s available for all popular operating systems.

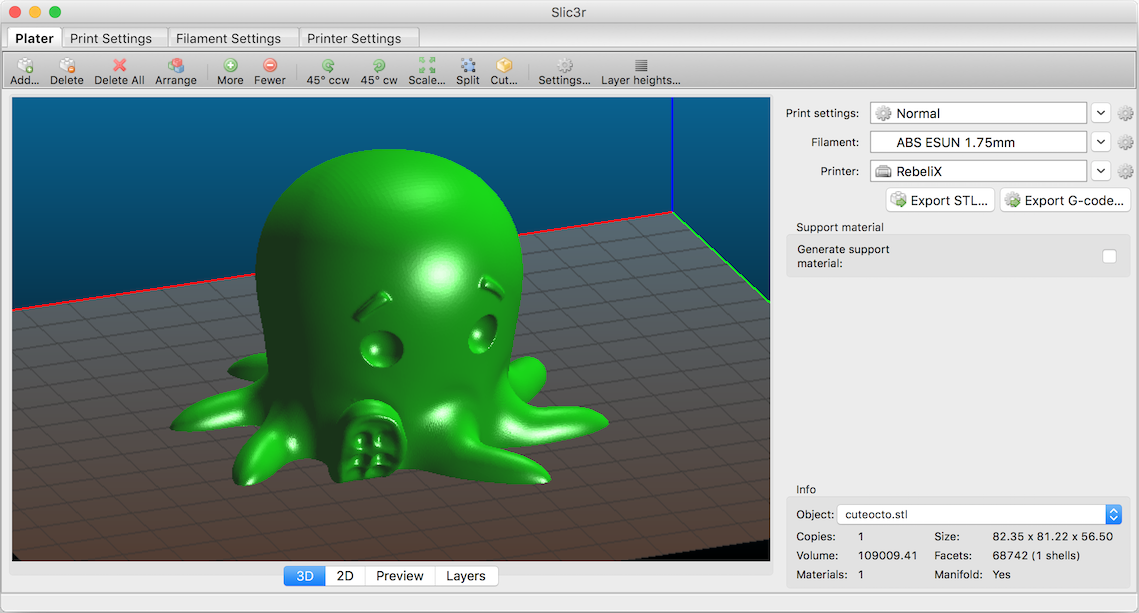

We’ll import an STL model we want to print into this program, then set the correct printer configuration (its dimensions and what functions it has) and set print parameters (temperatures, speeds, etc.). The output is a GCode file – print data that can be sent to the printer.

In exercises we’ll use the latest version of Slic3r ≥ 1.3.0. In this version, individual tabs can be opened in the Settings menu.

Configuration File for Printers

Download the configuration bundle for Hybrix printers that we use in this exercise.

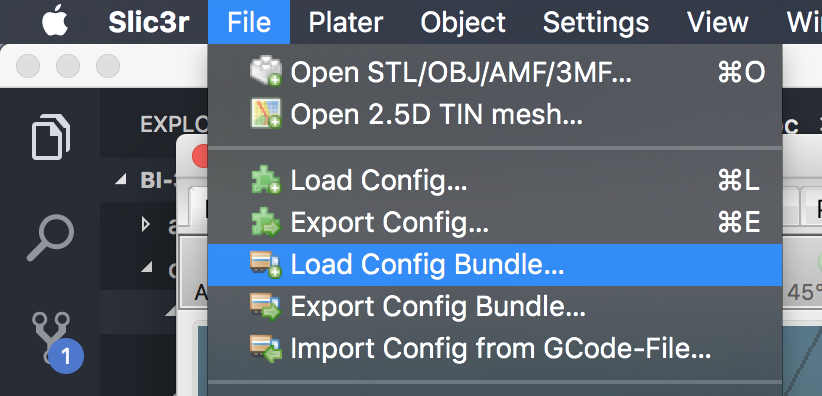

Load this file using File → Load Config Bundle. After loading the config bundle, it’s often necessary to restart the program. You’ll recognize successful loading of the config bundle by new items in the upper right (in filament, PET will appear as an option, and in printers Hybrix).

Upozornění:

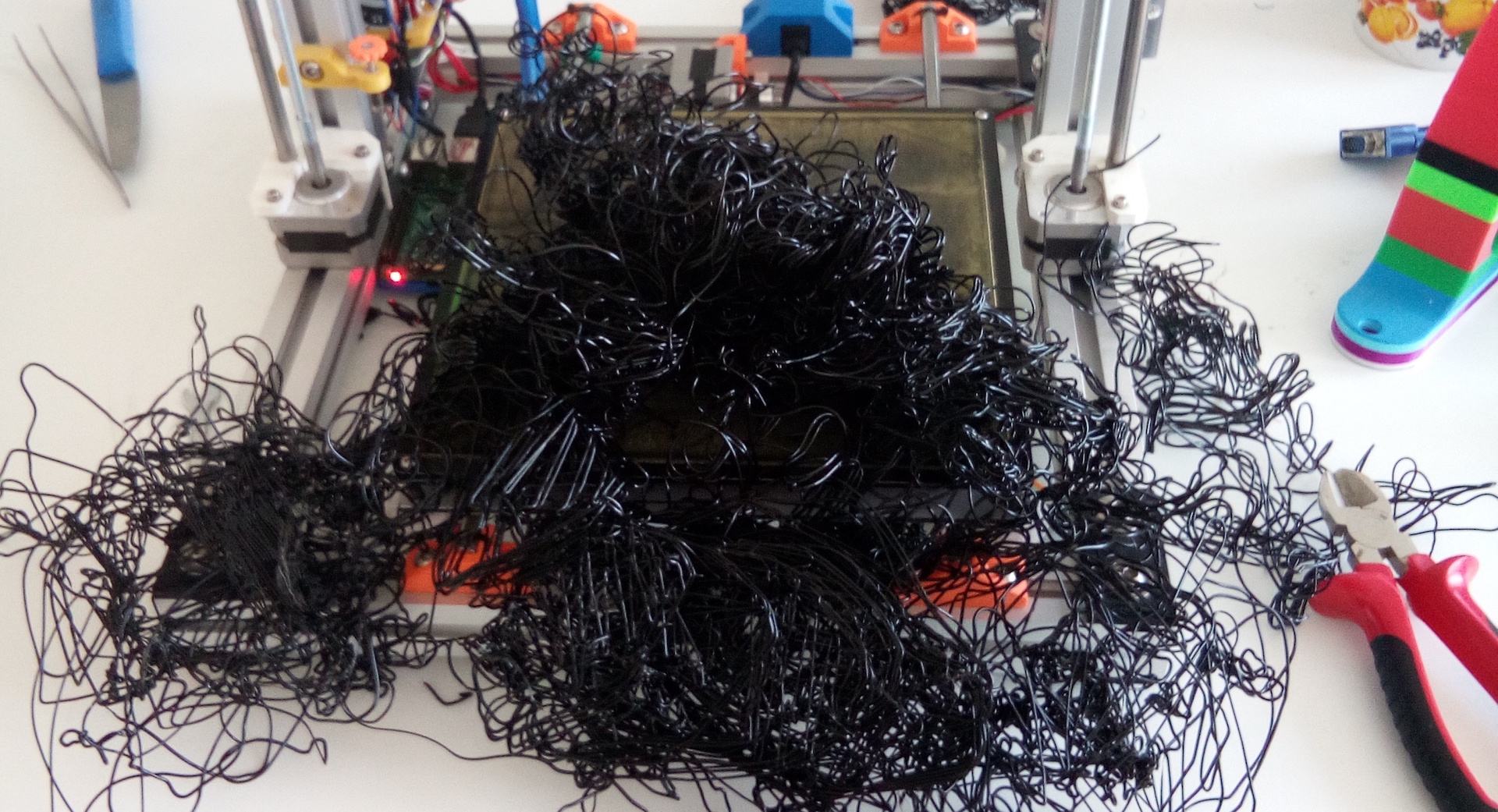

Setting the correct configuration file is important. Improperly chosen configuration can cause GCode to contain instructions unsuitable for the given printer (e.g., it may start printing outside the printable area) and such instructions can cause unsuccessful printing, or in the worse case damage the printer.

Supporting Structures

Besides the 3D model itself that you provide to the slicer, the slicer can add other structures that aren’t in the 3D model. These are structures that help during printing – for better adhesion, for printing overhangs, etc.

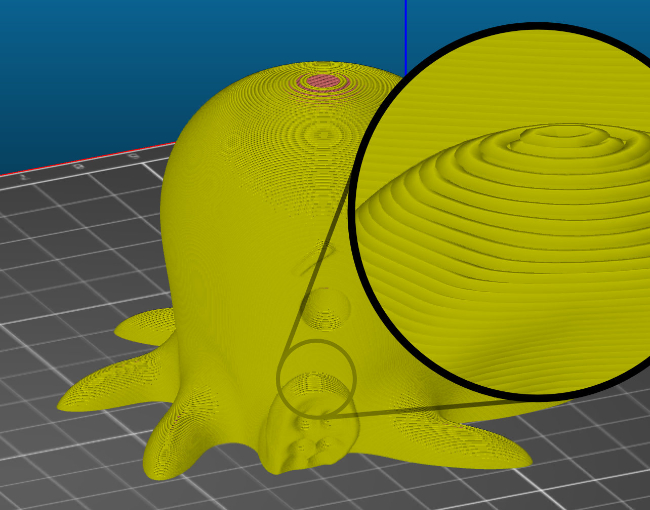

Model Interior

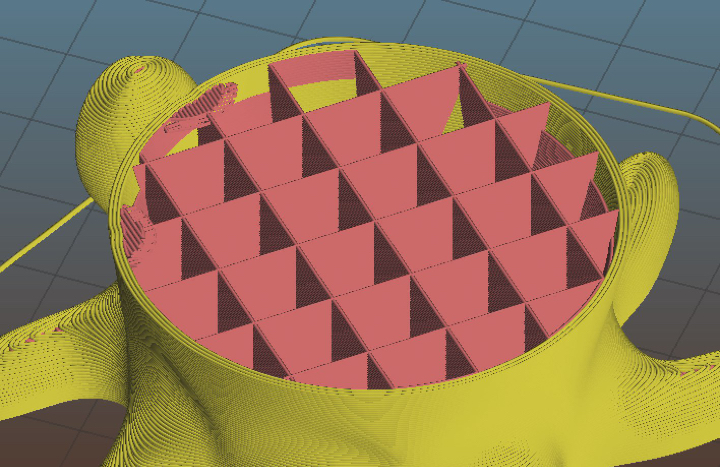

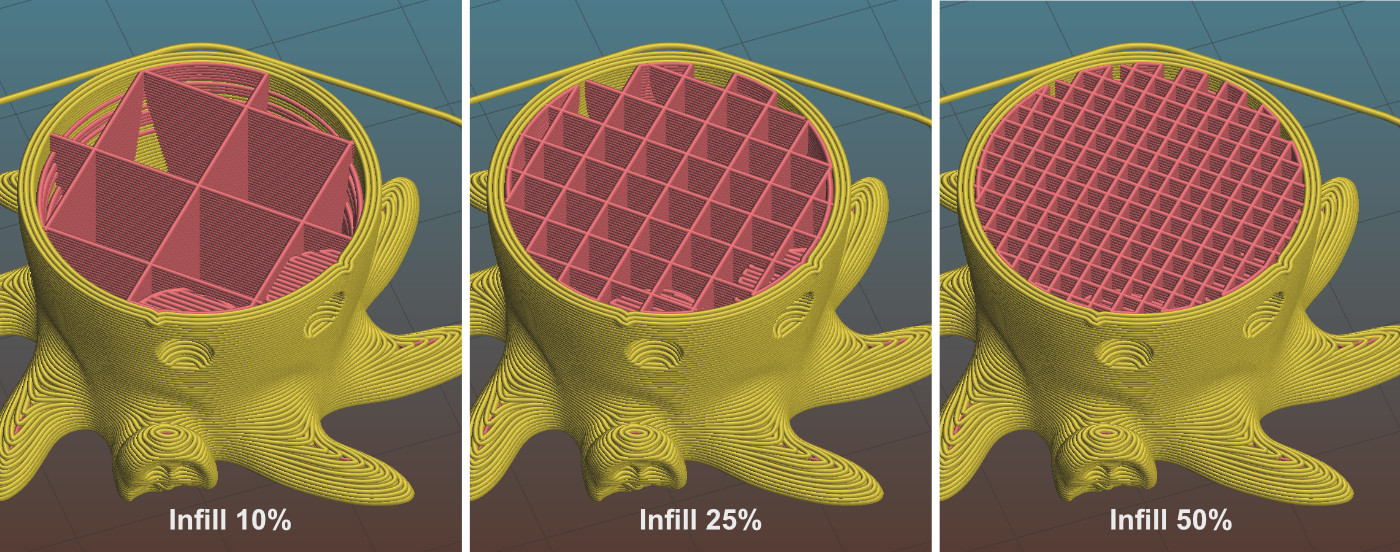

In previous exercises you learned that with mesh we describe only the object’s shell, not its interior. Physically on the printer, however, you cannot print only this shell. The slicer takes care of creating the correct object fill. This fill is called "infill" (fill).

Objects are commonly not printed hollow (the top of the object would have nothing to print on) nor solid (wasting filament and stress arises in the object that disrupts print integrity). Higher infill density makes the object more resistant, heavier, but also more expensive and takes longer to print. Low density can conversely cause an unsightly print (the object’s shell can sag in some places). In practice, infill is not set to a value lower than 10% nor higher than 50% for a general object. However, there are shapes that can be printed hollow or with very small infill.

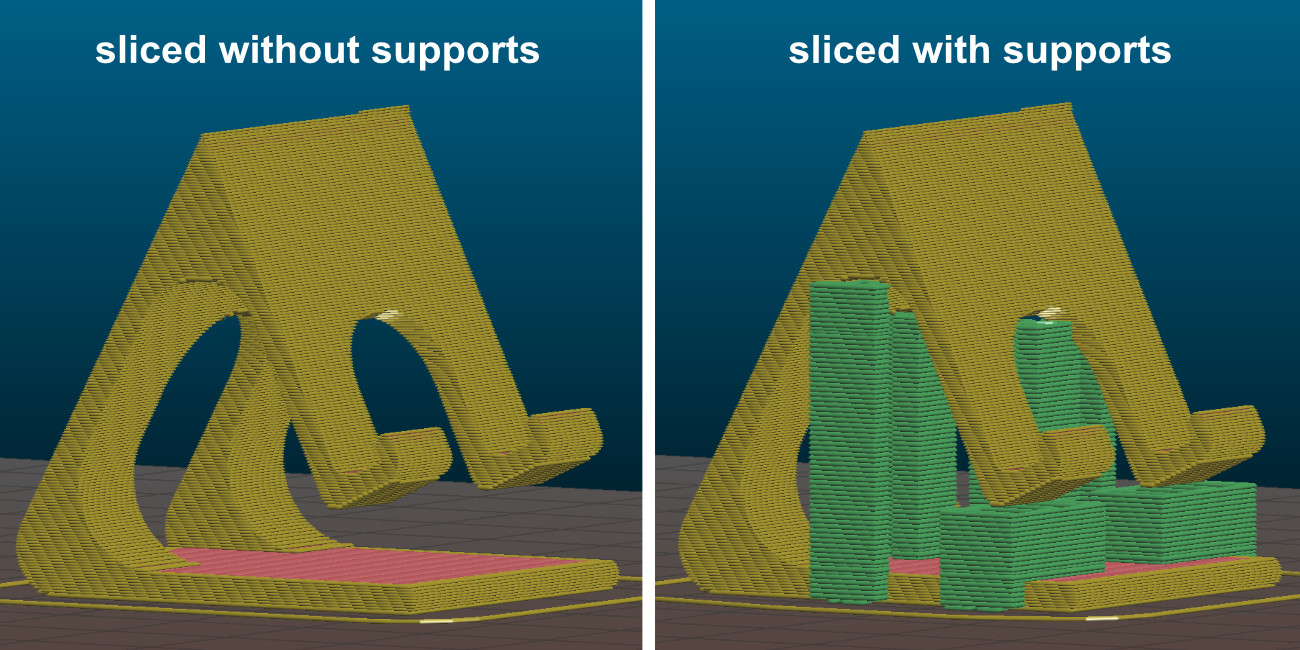

Supports (supports)

It often happens that we need to print a model with overhangs. For obvious physical reasons, such printing on FDM printers is not possible (the printer would be printing into air).

Often these problems can be solved by rotating the model or dividing it into multiple parts and subsequent manual gluing after finishing the print. Sometimes such modifications are not possible or desirable, and so the slicer can add supporting structures to our model that are broken off, cut off, or otherwise removed after finishing the print.

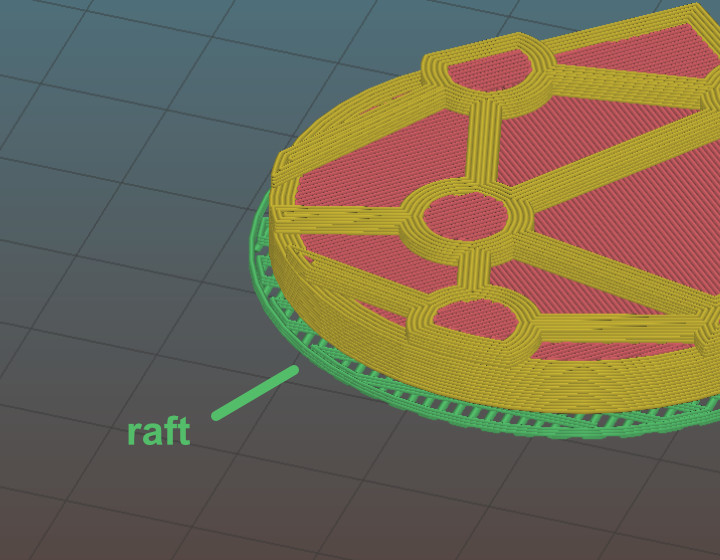

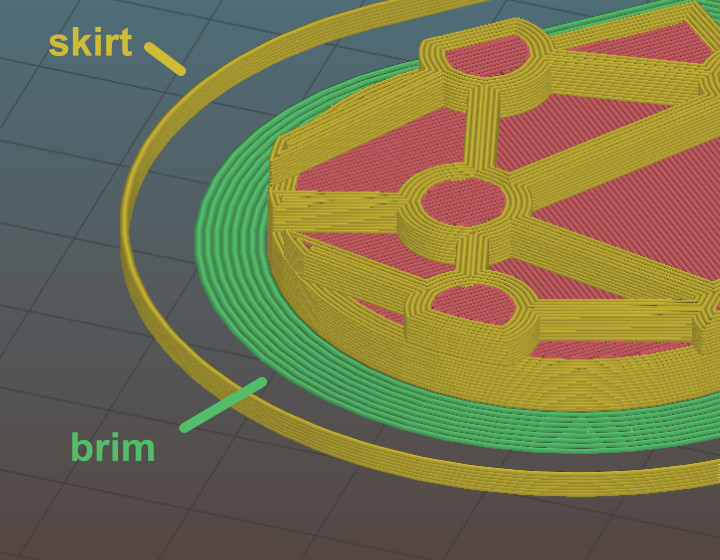

Rafts, skirts, brims

Certain types of prints have problems with adhesion to the print bed surface. During printing they can then detach and at that moment the print becomes unsuccessful.

Problematic are primarily such models that have too small a contact area with the print bed and the area holding the object is too small (imagine for example a table model that we start printing from the legs – the entire object is held only by four small squares).

- Raft

- A structure placed under the print improving adhesion to the print bed. Rafts are intended primarily for ABS materials, whose print edges curl during printing. They’re also useful for models that have too small a contact area with the print bed. They create a much larger adhesive base for them. A raft is created by moving the object several layers upward (into air) and underpinning the object with support.

- Skirt

- An outline structure ensuring stable plastic flow during the first layers of printing. It’s printed before the first layer of the object and thanks to this, all air bubbles are extruded from the nozzle and plastic flow stabilizes. Some slicers use other structures for these purposes (e.g., Prusa Slic3r makes a line the width of the print bed at the very edge of the bed). You can also set a higher number of skirt layers and thus also use it for protecting the print from drafts and subsequent cracking, but in practice this method is rarely used, as it unnecessarily increases material consumption and print time; moreover, it’s very unreliable protection (it’s better to put the printer in a cabinet).

- Brim

- Another structure improving adhesion to the print bed and reducing edge curling. Technically it’s a skirt with zero distance from the model and a height of one layer. It’s not located under the print, but only extends the first layer by a specified size. Brim doesn’t offer as much adhesion improvement as Raft, however, it’s much faster, simpler, unlike Raft doesn’t leave unevenness on the bottom of the model, and for most cases is sufficient.

Print Configuration in Slic3r Program

Now we’ll move on to what can be set in the Slic3r program and what it’s good for.

Tab Plater

On the Plater tab, you work with objects you want to print. With the Add button you can add an STL file. In the 3D preview you can arrange objects across the print bed. With other buttons in the top panel you can manipulate the selected object (rotate with Rotate buttons, or change its size with the Scale button).

On the lower right, information about the selected object is displayed. You can see its size in millimeters (for checking) and other properties.

At the bottom you can select from several views; primarily important for us are 3D and Preview views. In 3D view you can work with object arrangement; Preview view shows you how the final print will look, what structures will be printed, and you can even see a hint of individual layers.

Tab Print Settings

Pay the most attention to the Print Settings tab. While most important values in other tabs were set for you by the configuration file you downloaded above, print settings will be your main task when working in exercises.

Below we’ll list all important parameters you’ll use when printing in exercises. If you want to learn something about parameters we don’t mention, we recommend choosing one quiet evening over the Slic3r manual for self-study.

Page Layers and perimeters

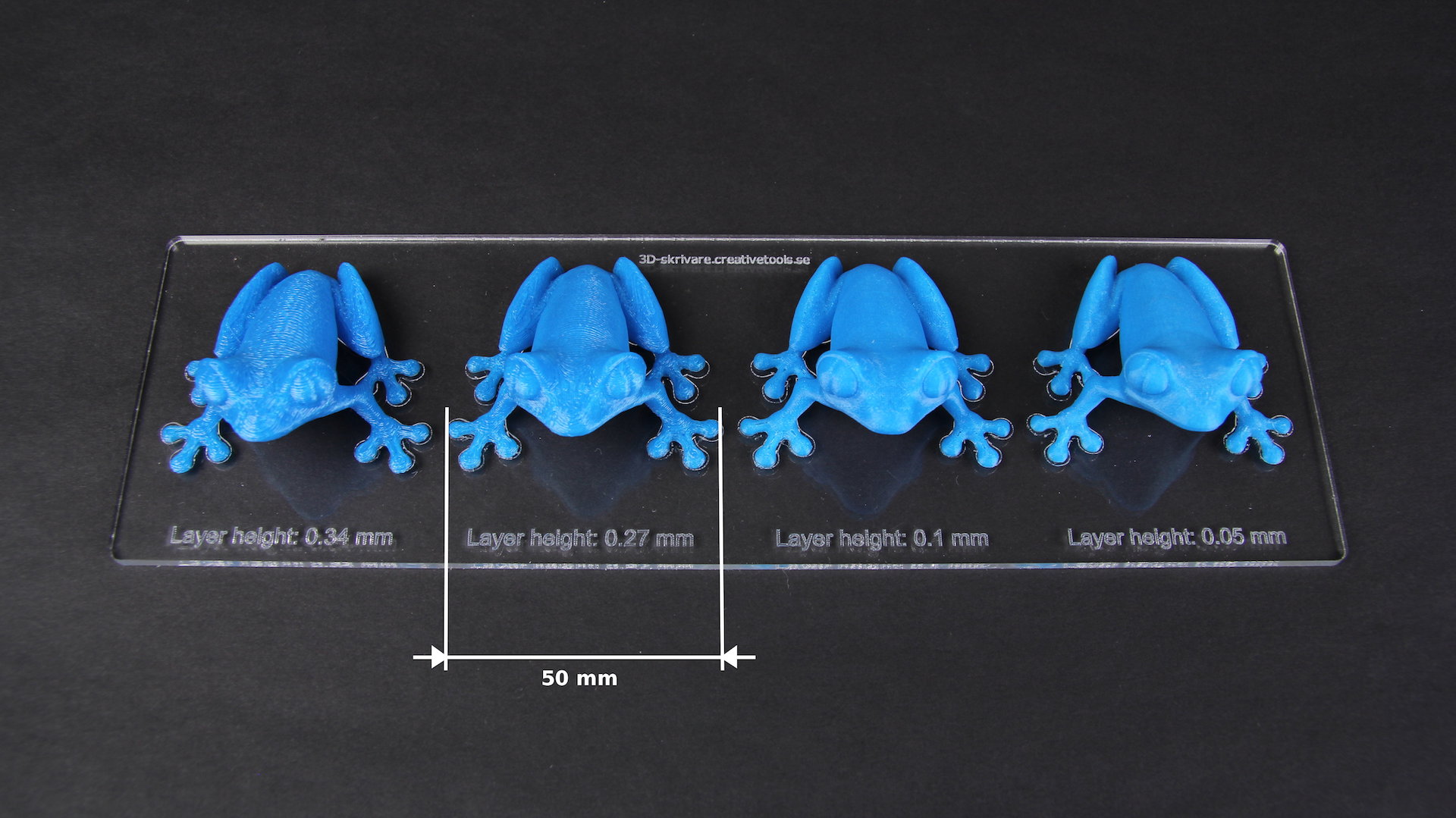

- Layer height

- Affects layer height – directly affects quality and print duration. The range of sensible values is affected by the nozzle diameter installed on the printer.

- First layer height

- Affects the first layer height. Set to a smaller value than the rest of the model for better adhesion to the print bed.

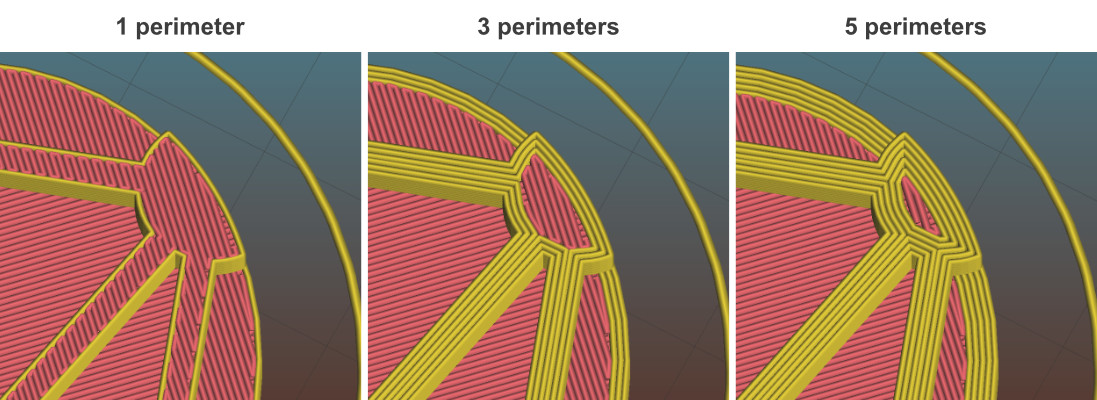

- Perimeters

- Number of perimeters on print edges (doesn’t affect flat surfaces on the bottom and top of the object).

- Solid layers

- Number of layers with full fill on bottom and top. The more layers we choose, the stronger the top and bottom surface will be and the better we’ll manage to cover the set infill. High numbers, however, increase print time and material consumption.

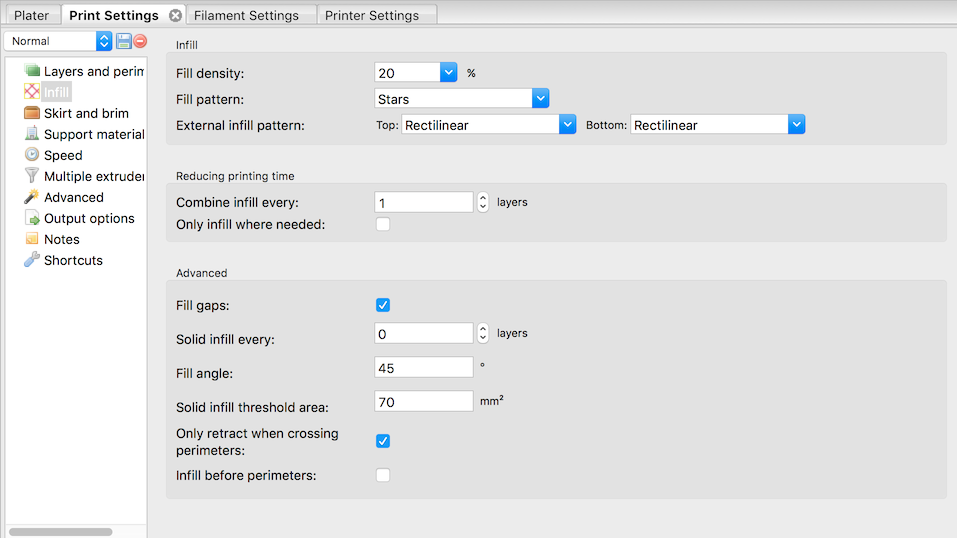

Page Infill

On this page you can set infill properties, which we know from the chapter Model Interior.

- Fill density

- Determines internal fill density.

- Fill pattern

- Determines fill pattern.

- External infill pattern

- Determines fill pattern on top and bottom external surfaces.

- Solid infill every

- Strengthens object resistance by printing full fill (100%) every n layers.

- Fill angle

- Fill pattern angle.

- Solid infill threshold area

- In small parts of the object (e.g., some thin tubes or connector), the slicer fills with full fill (100%). This value determines the area threshold at which a part of the object is considered small.

Page Skirt

On this page you can set Skirt or Brim.

- Loops

- Number of skirt outlines. For common use for cleaning the nozzle before printing the first layer, in most cases one or two suffice.

- Distance from object

- Distance of skirt from object.

- Skirt height

- How many layers the skirt will be high. For cleaning the nozzle, usually only one is used.

- Exterior brim width

- Non-zero value will generate a brim around the object of specified size.

Page Support material

On this page you can set supports or raft.

- Generate support material

- Turns on support generation.

- Overhang threshold

- Determines the threshold for how steep overhangs you want to generate supports. Can be set in percentages: how many percent of the perimeter can the next layer still overhang the layer below it (the higher the number, the fewer supports); or in degrees (incline from base, the higher the angle, the more supports).

- Raft layers

- Determines how many raft layers you want to print under the model.

Other Tabs

The Filament Settings tab, as the name suggests, hides settings related to filament. The most important items are Diameter (determining string diameter) and temperature settings, which differ by material (as you’ll learn in the first printing exercise). On the Cooling page you can then define fan behavior for additional print cooling (some materials need it, but our printers don’t have it).

The Printer Settings tab serves for setting printer parameters (size and shape of print bed, number of extruders, etc.). While items on the Print Settings and Filament Settings tabs you change practically with every print, items on this panel mostly remain untouched until you change printer configuration.

The configuration file sets most of these parameters. Nevertheless, we recommend briefly going through these parameters; those interested in examining parameters in detail we’ll again refer to the Slic3r manual.

Slicing Step by Step

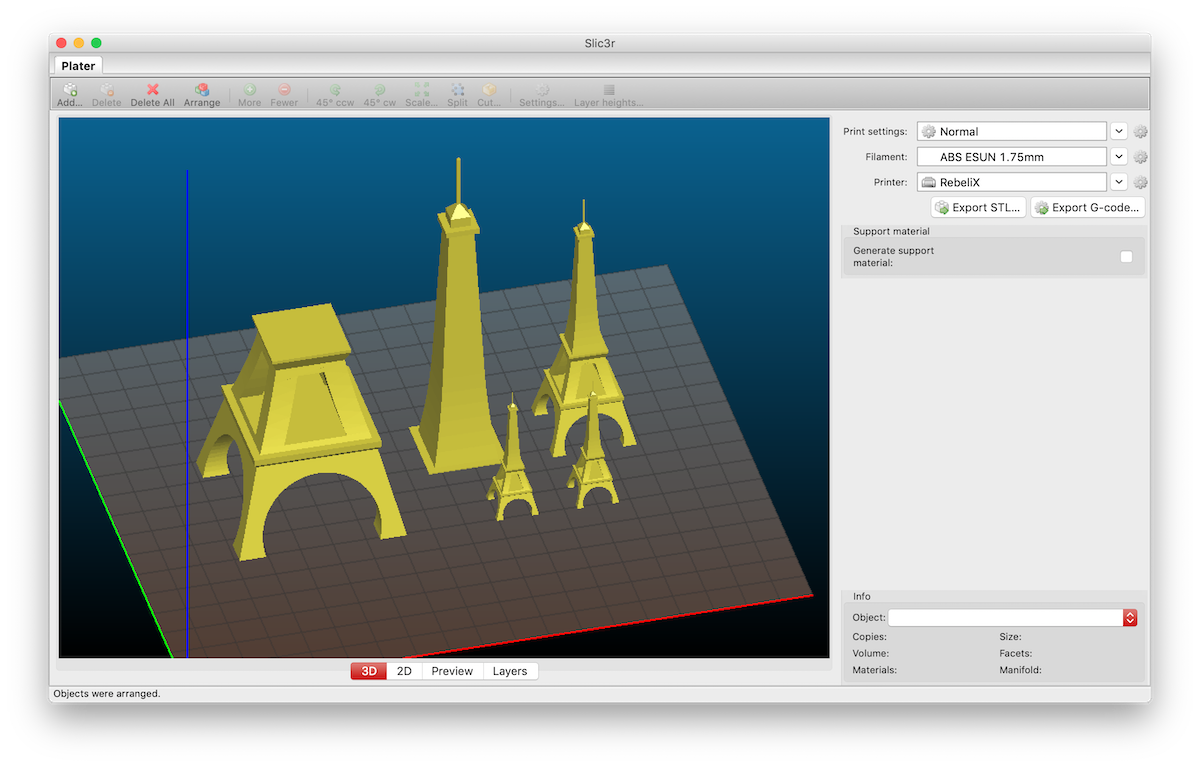

In this chapter we’ll show the entire slicing process on one simple example model. For slicing we’ll use a very simplified model of the Eiffel Tower, which can be safely scaled.

We want to print the model four times: once at double size, once at full size, and twice at half size (1× 200%, 1× 100%, 2× 50%). For the full size, however, we fear that the tower will be taller than the printer can reach, so we’ll divide this variant into two parts and glue it after finishing printing. We’ll consider the print as experimental and so we’ll set parameters so printing is as fast as possible, but at the same time succeeds and the result is at least minimally aesthetic (it shouldn’t be ugly). We fear that the printer won’t handle overhangs at the bottom of the Eiffel Tower, so we’ll add supporting structures. We also have concerns that during printing the legs might detach from the print bed, so we’ll add structures for improving adhesion.

Důležité:

Before actually preparing print data, we’ll make sure we have the correct config bundle imported in Slic3r. It can be downloaded on this page. Import it into Slic3r using Load Config Bundle, not using Load config.

Loading Model and Simple Modifications

- On the Plater tab, using the Add button in the top toolbar, add the STL file to the print bed.

- With the More button in the toolbar, duplicate the model to two copies.

- With the Scale button in the toolbar, set object size to

25 %. This is the object size relative to the original size. So the number states the given size; if we set size to50 %twice, the resulting size won’t be25 %, but still50 %. - With the left button in the 3D preview window, arrange objects as needed. With the Arrange button we can have objects automatically arranged.

- Object scaling always affects all copies created using the More button (this generally applies to all object modifications). To be able to insert two different sizes of the same object, we must use the Add button to upload the STL file again, thus creating a new object that will already have independent size settings. Set its size to

50 %. - As the last one, insert the same object again using the Add button and perform bisection. The Cut button in the toolbar serves for this. A dialog opens where we set the desired height at which the cut is performed. Check both checkboxes Upper part and Lower part, since we want to keep both parts after the cut.

- The result should look similar to the sample screenshot. If we’re satisfied with the print layout, we can move on to setting print parameters.

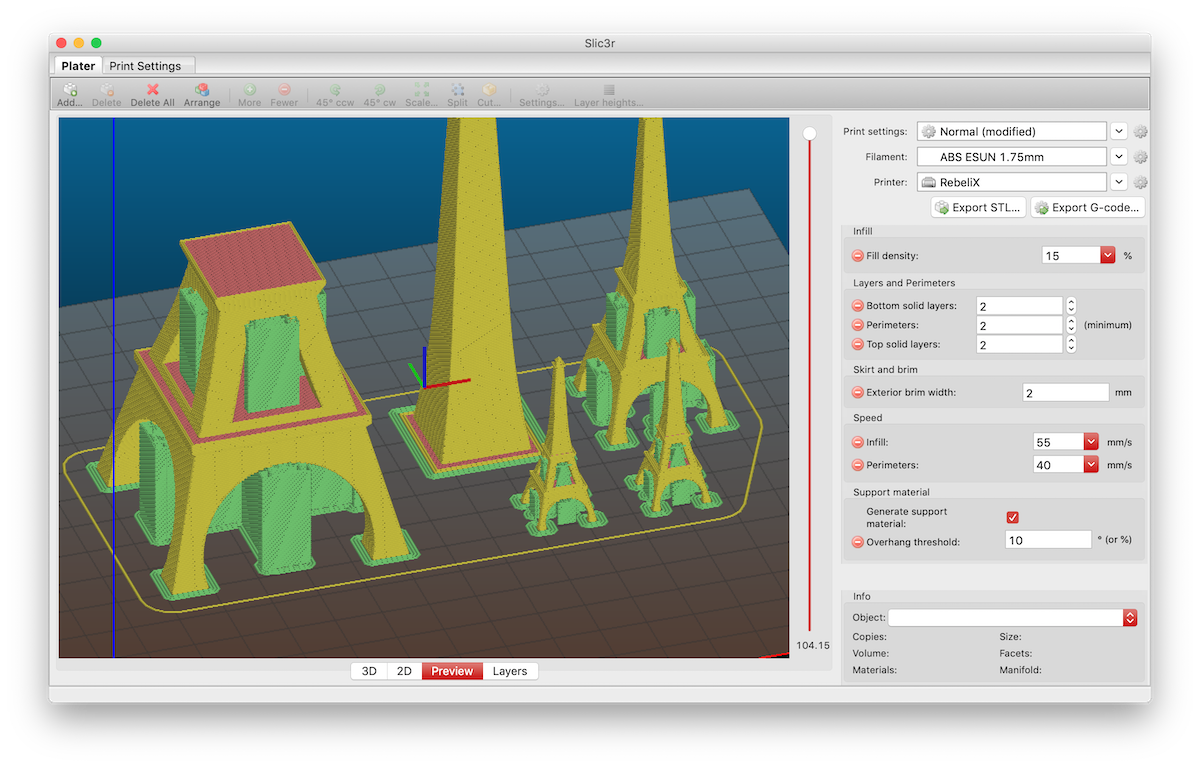

Setting Print Properties

- In the lower part of the Plater tab there are buttons for selecting the view. When setting print parameters, the Preview view is useful, which not only gives a preview of how the final print will look, but also displays all additional structures we set in print parameters. With the slider located to the right of the preview window, we can examine the preview more closely. By moving the slider from bottom to top, we simulate the print progress. We can thus check each change in settings on this tab.

- Open the Print settings tab in the menu Settings → Print Settings.

- On the Layers and perimeters page, set the number of perimeters to

2(item Perimeters), full layers on bottom and top also to2(item Solid layers). - On the Infill page, set fill to

15 %. - On the Skirt and brim page, arrange for a structure for better adhesion to be printed. Set Exterior brim width to

2 mm. - On the Support material page, have supports printed in places where there’s a large overhang. Check the Generate support material option. We more or less trust the printer and believe it can handle overhangs from 10° and more. Set Overhand threshold to

10°. - On the Speed page, speed up printing at the expense of quality. Increase perimeter print speed by

5 mm/sand infill print speed by10 mm/s. Set Perimeters to40 mm/sand Infill to55 mm/s. - Export the result using the Export G-code… button on the right side of the interface.

Credits

Models appeared in images:

- Cute Octopus Says Hello by MakerBot (CC BY 3.0)

- Phone Stand by GoAftens (CC BY 3.0)

- Eiffel Tower by bmfinn (CC BY-SA 3.0)