Printing: Multi-color Printing

You’ve surely noticed that our printers print with such material (in such color) as we load into them. There are various possibilities how to get rid of this limitation, or at least slightly circumvent it.

Why print from multiple materials at once? The first reason can be aesthetic.

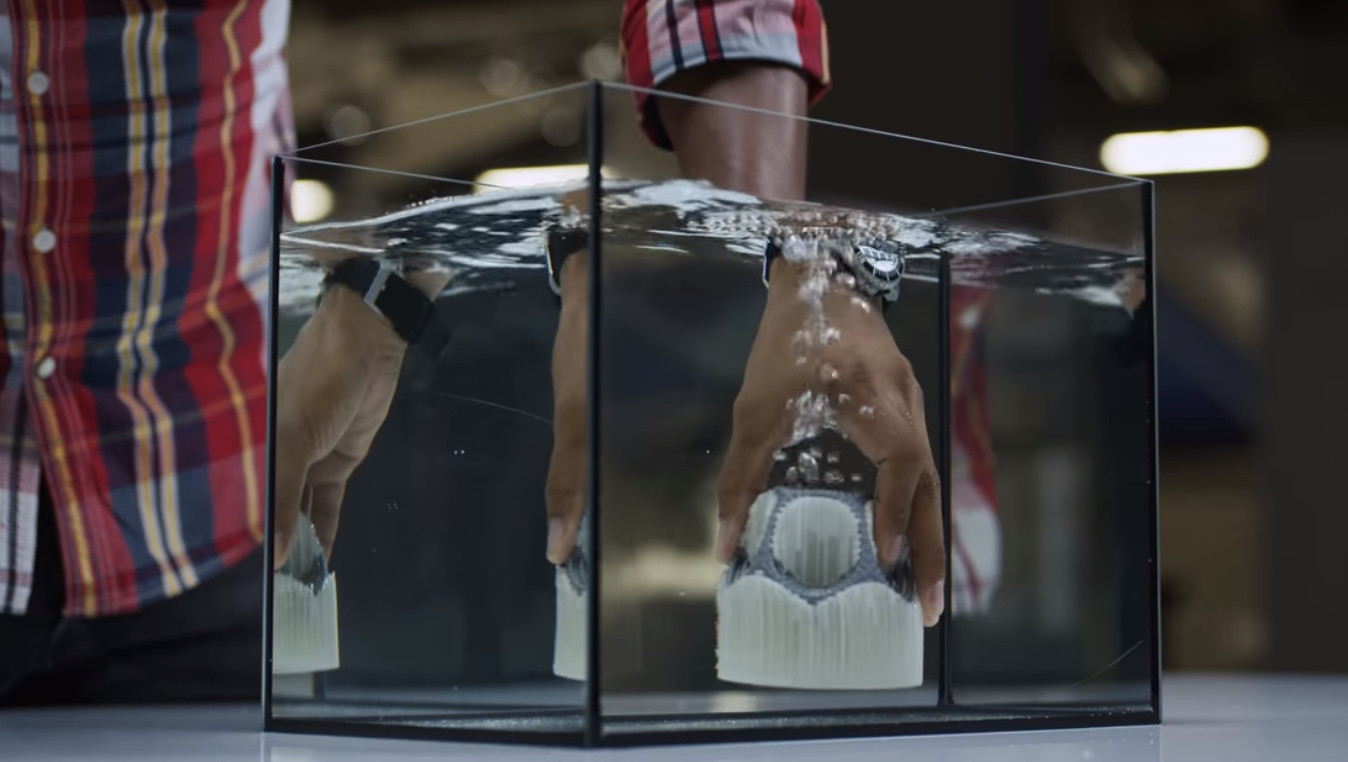

Another reason can be printing supports from a different material, for example one that dissolves in water (PVA) or in a common cleaning agent (HIPS).

Sometimes such materials can be more expensive and therefore only the interface (several layers) between the support and object is printed from them.

Multi-material and Multi-color Printing Options

Multiple Nozzles

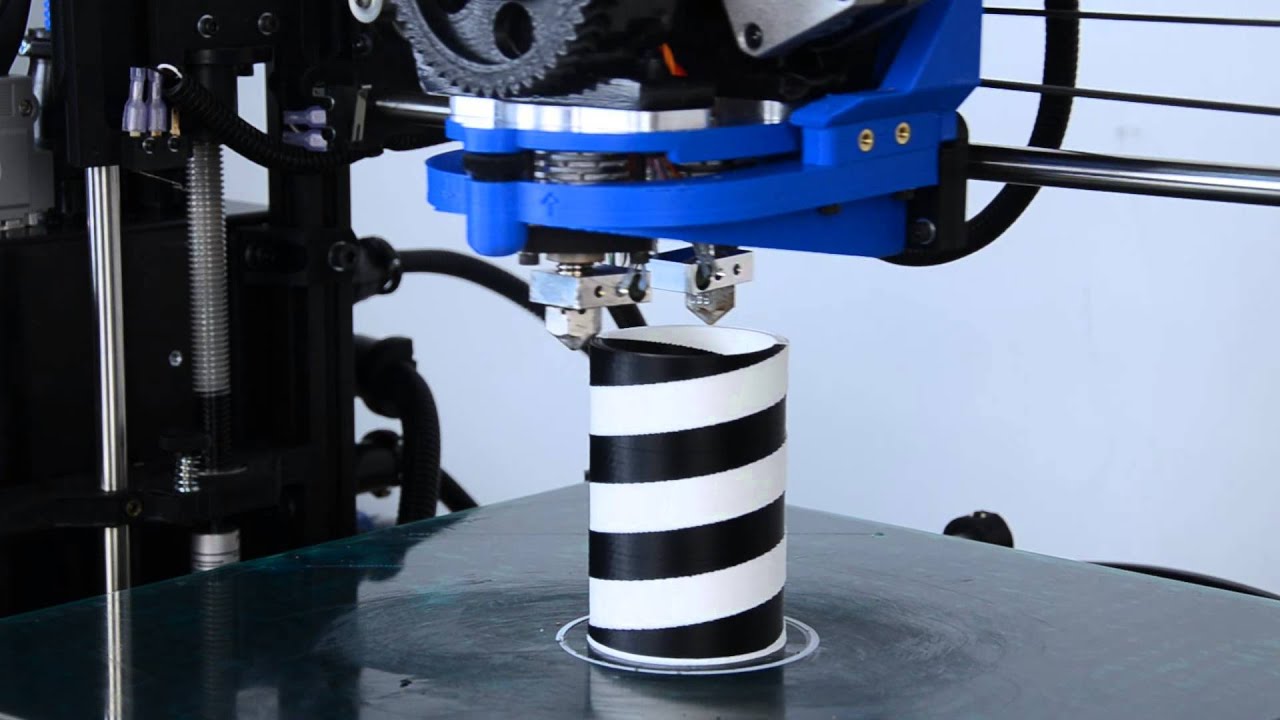

One option for printing from two (or more) materials simultaneously is to use two (or more) nozzles.

The print area then shrinks somewhat and the printer prints with one or the other nozzle as needed. The disadvantage is that the mutual position of the nozzles must be very precise and that plastic can leak from the nozzle that’s not currently being used (like when you preheat the printer before printing).

Multiple Extruders

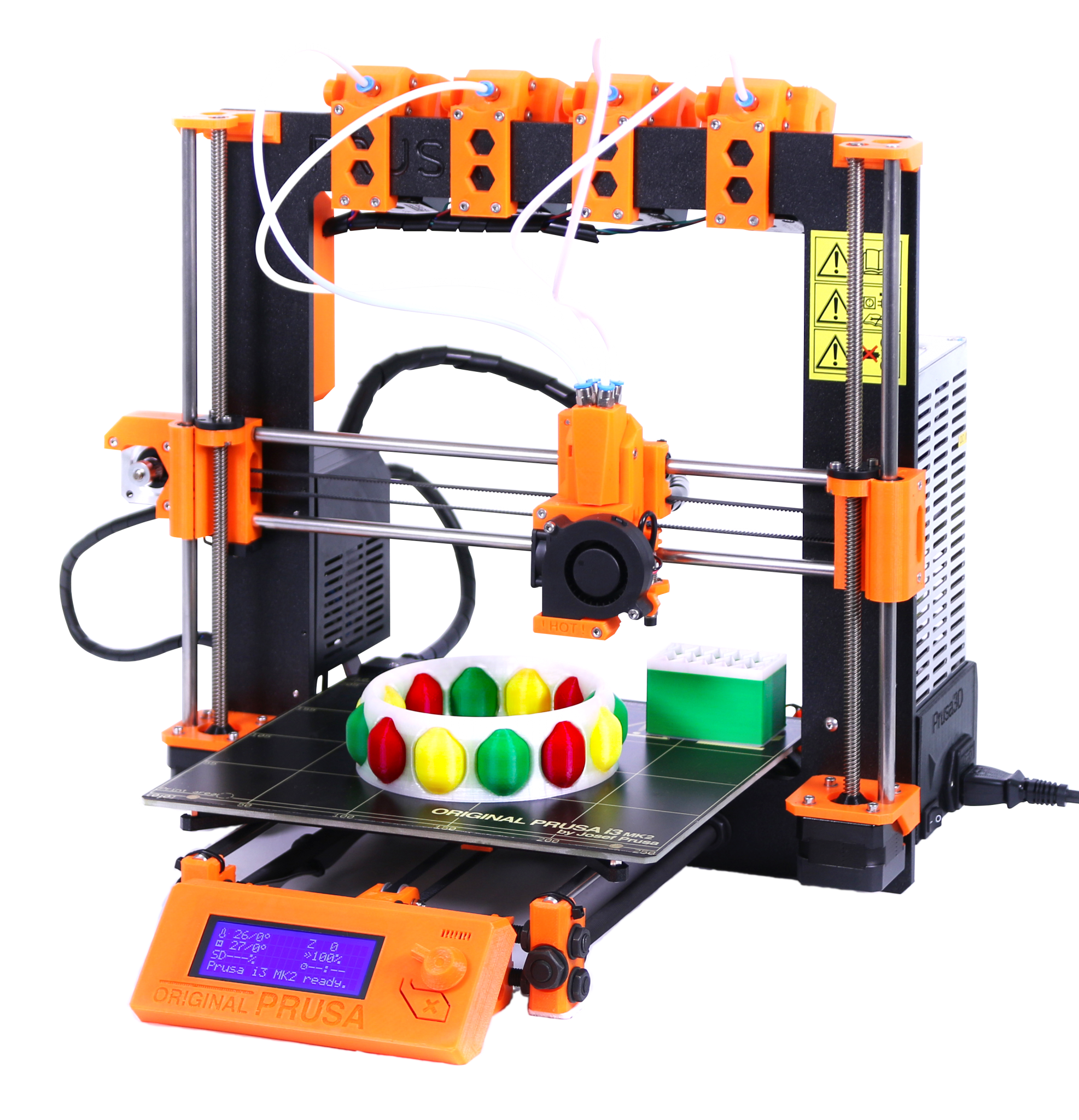

Another option is to alternately push multiple different plastics into one nozzle.

When changing material in one nozzle, excess old plastic must be extruded somewhere. This is usually done into a waste object, which can be very financially wasteful.

Even with One Print Head You Can Put on a Great Show

If we have a printer with only one extruder and one nozzle available (as in the BI-3DT course), multi-material printing is almost unavailable or at least very difficult for us. However, there is one type of multi-material printing that we can perform with a bit of skill, and that’s division along the layer:

Procedure

Důležité:

For today’s exercise, download the general Config Bundle for Slic3r.

Varování:

Follow all safety rules from the printing exercise. Especially don’t eat filament and don’t touch the hot printer nozzle.

Basic idea: We’ll split the GCode into multiple files so we can change filament between them. We assume printing a traffic cone from the image above.

- We’ll have GCode generated for the entire cone.

- We’ll find a suitable layer where we want one color to end and another to begin, we’ll split the Gcode into two files (see below).

- We’ll repeat the previous step as many times as colors change.

- We’ll add the

G28 X0 Y0command (home X and Y axes) to the beginning and end of each newly created GCode. - We’ll start printing the first file.

- When the first color finishes printing, we’ll change the material and start the next file.

- This way we’ll change material and print subsequent Gcode files until we finish printing the entire object.

Where to Split GCode?

To properly split a GCode file, you need to split it in the right place. The right place in our case is immediately after the command determining transition to the next layer. Here’s a piece of Gcode where we assume that everything from 5.1 mm height upward should be from a different material.

...

G1 X119.919 Y103.127 E0.03280

G1 X118.373 Y101.581 E0.11756

G1 X118.373 Y102.191 E0.03280

G1 X119.309 Y103.127 E0.07117

G1 X118.699 Y103.127 E0.03280

G1 X118.373 Y102.801 E0.02479

;BEFORE_LAYER_CHANGE 1

G92 E0.0

;5.1

G1 Z5.100 F12000.000 2

;AFTER_LAYER_CHANGE 3

;5.1

G1 X126.883 Y103.383 F12000.000

G1 F900

G1 X118.117 Y103.383 E0.45795

G1 X118.117 Y94.617 E0.45795

G1 X126.883 Y94.617 E0.45795

G1 X126.883 Y103.323 E0.45482

G1 X127.280 Y103.780 F12000.000

...- comment generated by Slic3r, may not be in every Gcode

- this line is crucial – we split the file after it

- comment generated by Slic3r, may not be in every Gcode

...

G1 X119.919 Y103.127 E0.03280

G1 X118.373 Y101.581 E0.11756

G1 X118.373 Y102.191 E0.03280

G1 X119.309 Y103.127 E0.07117

G1 X118.699 Y103.127 E0.03280

G1 X118.373 Y102.801 E0.02479

;BEFORE_LAYER_CHANGE

G92 E0.0

;5.1

G1 Z5.100 F12000.000 1

G28 X0 Y0 2- transition to new layer

- home on X and Y axes

G28 X0 Y0 1

;AFTER_LAYER_CHANGE

;5.1

G1 X126.883 Y103.383 F12000.000

G1 F900

G1 X118.117 Y103.383 E0.45795

G1 X118.117 Y94.617 E0.45795

G1 X126.883 Y94.617 E0.45795

G1 X126.883 Y103.323 E0.45482

G1 X127.280 Y103.780 F12000.000

...- home on X and Y axes (the nozzle is already at the correct height)

Assignment

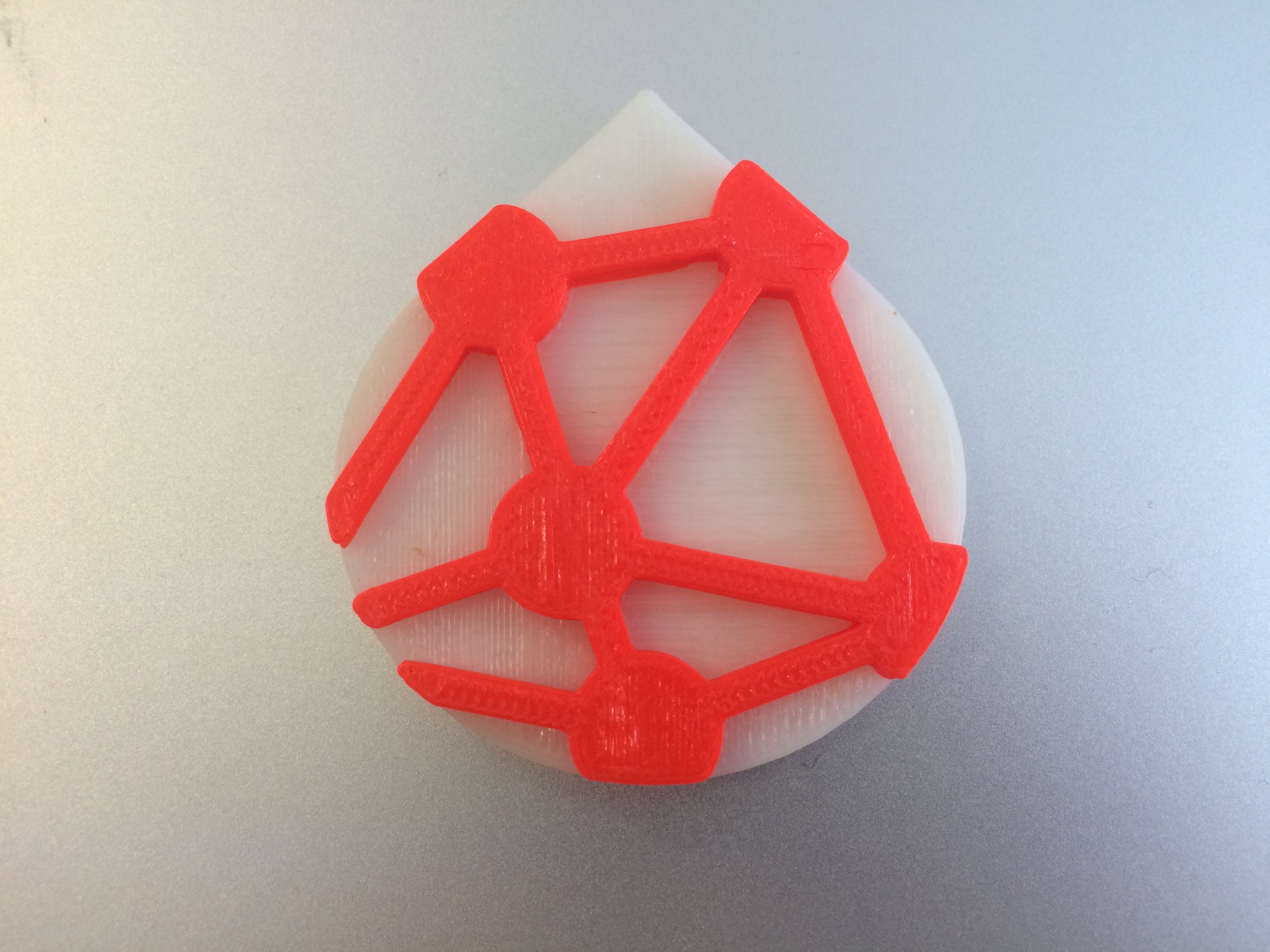

Print any number (but at least one) of two-color laboratory logos. Choose printing settings as needed, but base them on the Normal print profile. Arrange filament color exchange with classmates in the classroom, or ask instructors for an alternative color.

Grading: 3 points for completing the assignment and cleanup.