Printing Technology and RepRap

The purpose of this text is to briefly familiarize you with 3D printing, primarily with 3D printing using thermoplastic extrusion on open-source RepRap printers.

This is not an exhaustive theoretical analysis of individual technologies, nor a list of definitions, but rather a gentle introduction to the hardware we’ll encounter during the semester.

What is 3D Printing

3D printing is an automated process of converting a digital three-dimensional model into a physical solid three-dimensional object.

All 3D printing technologies have a common basic principle of laying layers on top of each other, which is called additive manufacturing. It’s the opposite process to machining material. Instead of the object being cut from a piece of material, it’s gradually manufactured from material.

A 3D model is "sliced" into thin layers, which are then laid using the printer one on top of another. We can imagine it as if we wanted to use a desktop printer to create a 3D object from paper. First we print all the necessary layers, then cut them out with scissors and glue them on top of each other. In such a case, we are a 3D printer.

What is 3D Printing Good For

3D printing is nowadays used primarily for these things:

- Prototyping

- Printing a prototype of a component or design element is cheap and relatively fast (on the order of hours). Serial production is (with very large quantities) still cheaper and more precise, but it’s not worthwhile for a prototype.

- Spare Parts

- Unavailability of spare parts (price, distance, existential…) leads many users to utilize 3D printing. Whether it’s gears for a wind-up toy, or nuts for a lunar module.

- Foundations for Other Products

- 3D prints often serve as a means to produce something else, often custom. For example, as a skeleton for a sculpture or a pattern for casting a mold.

- Improvements

- Humans are inventive creatures and that includes tinkering. On a 3D printer special parts are made for modelers, or household needs (hooks, closures, pegs, holders…).

- SWAG

- Last but not least, things are made for nerds and geeks.

3D Printing Technologies

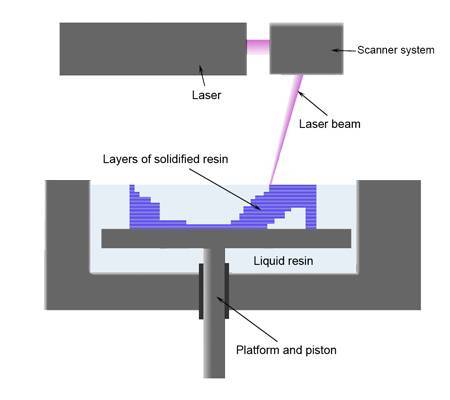

Stereolithography (SLA)

A method of creating objects from liquid polymer, which is gradually cured using radiation of various wavelengths.

Powder Printing (SLS, DMLS)

The technology is based on laying thin layers of powder and subsequent curing of only the necessary places. Curing can occur either by sintering powder with a laser (for example metal, DMLS), or using liquid polymer and irradiation usually with UV radiation.

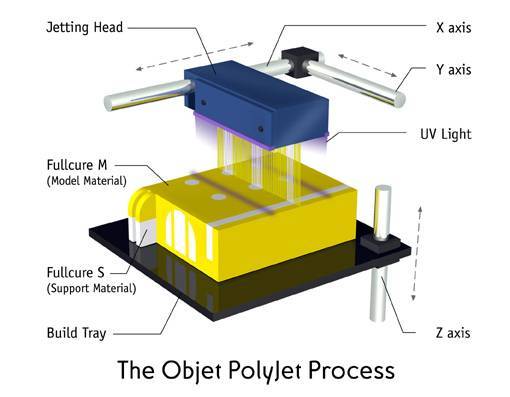

PolyJet

Similar to inkjet printers, polymer is ejected from the print head using miniature nozzles. Subsequently the layer is cured with UV beam. Video

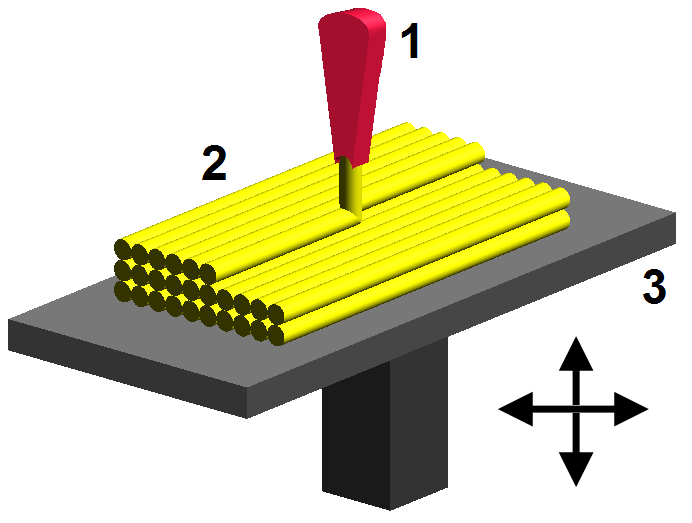

FFF/FDM/Thermoplastic extrusion

FFF (Fused Filament Fabrication) or FDM (Fused Deposition Modeling) is a technology that’s based on the principle of a "glue gun". Plastic is pushed into the nozzle where it’s melted and then laid on the platform.

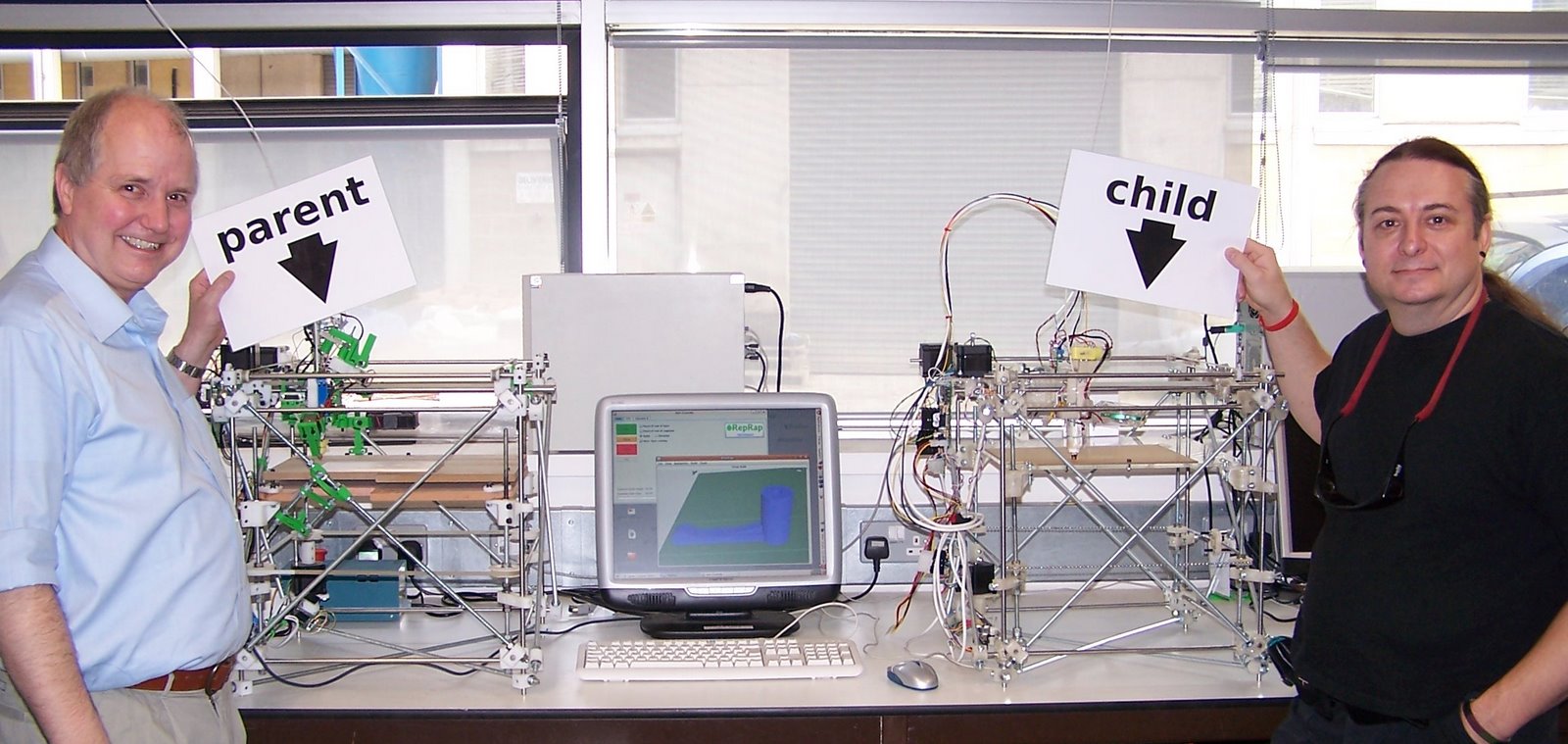

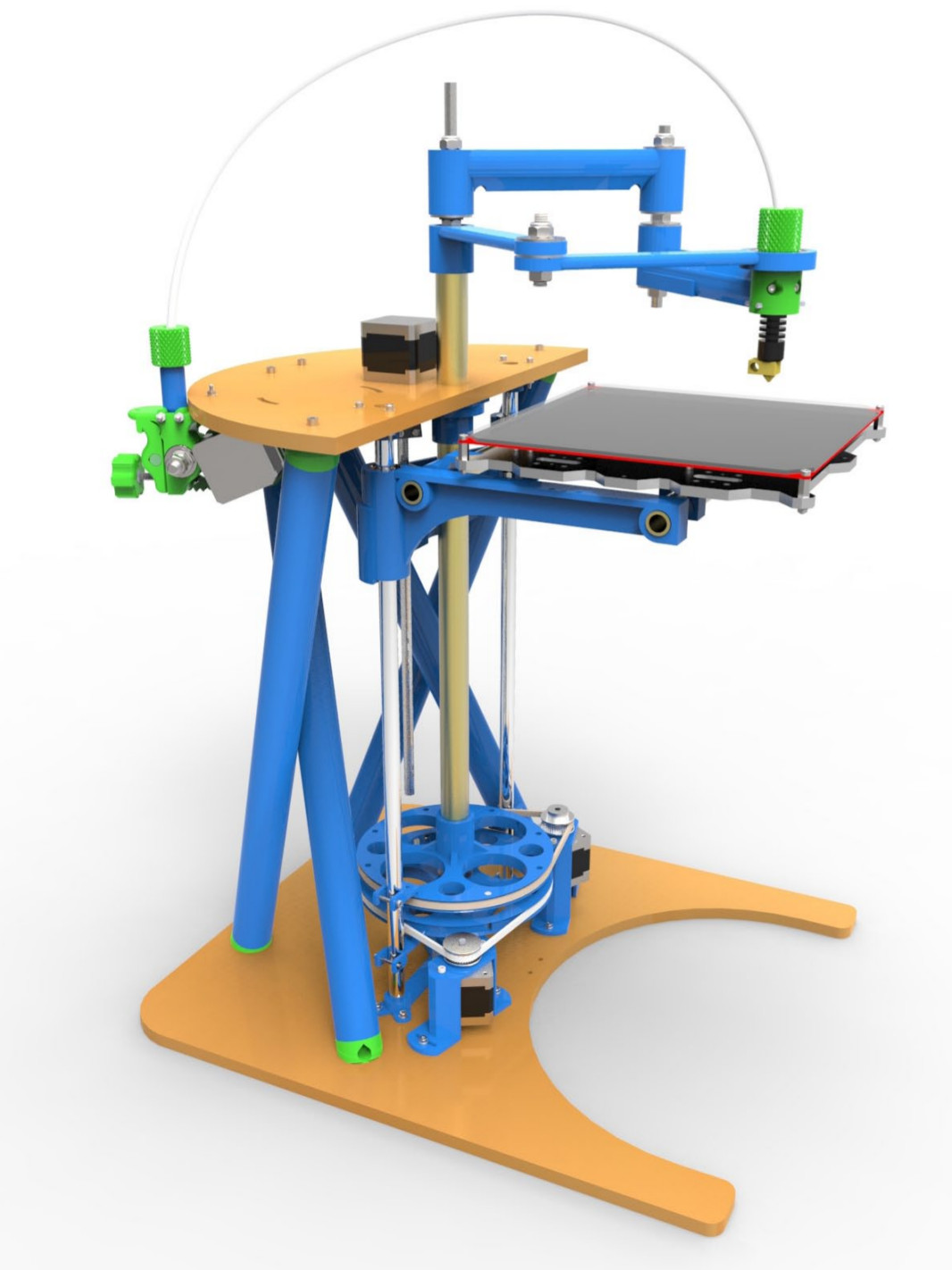

RepRap

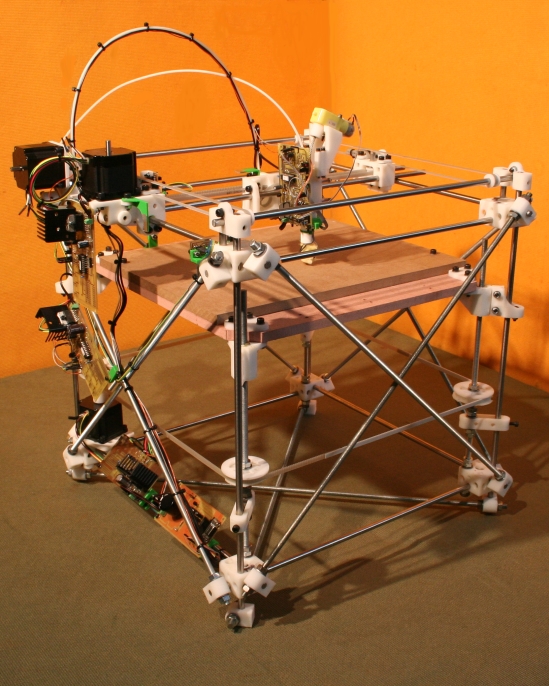

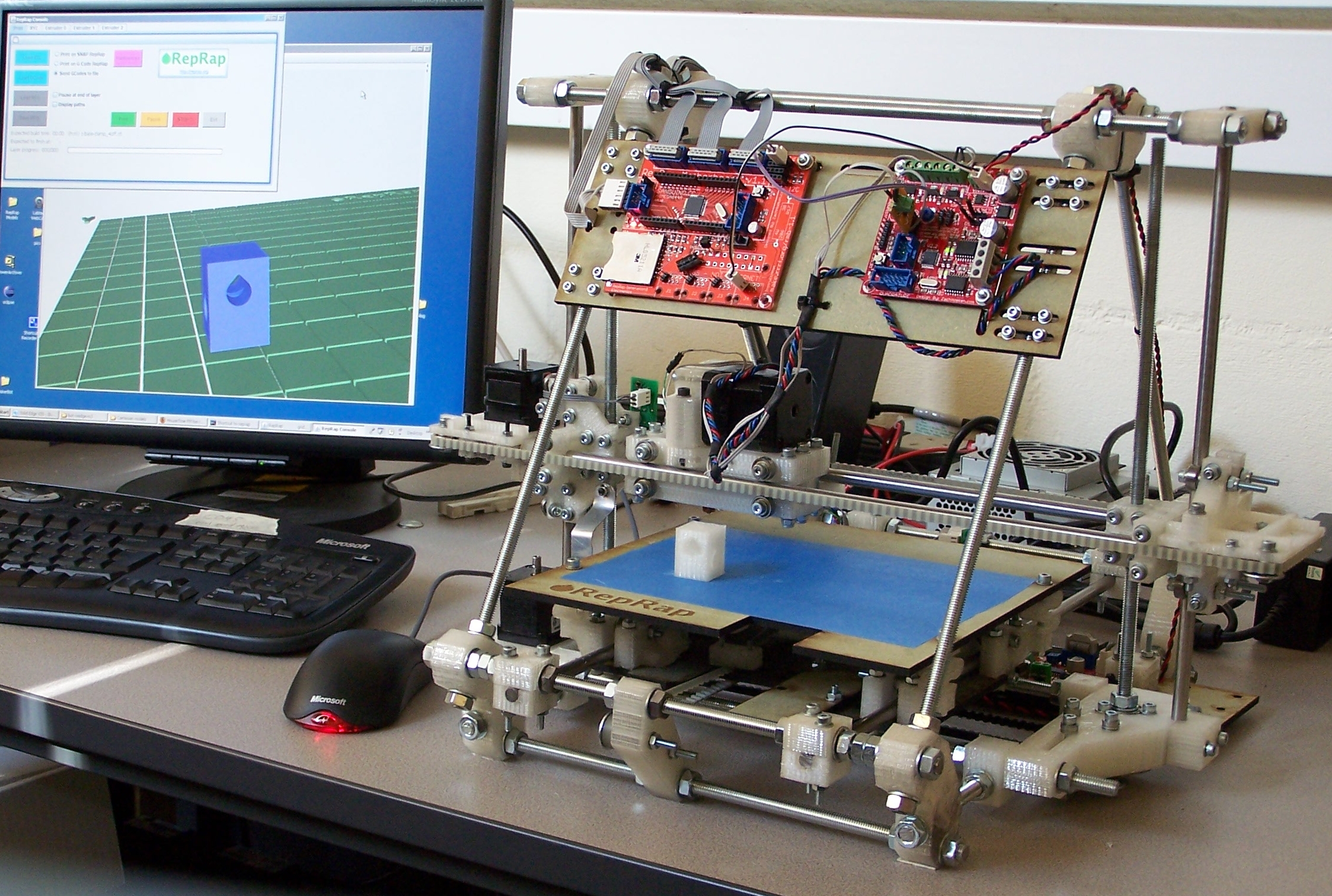

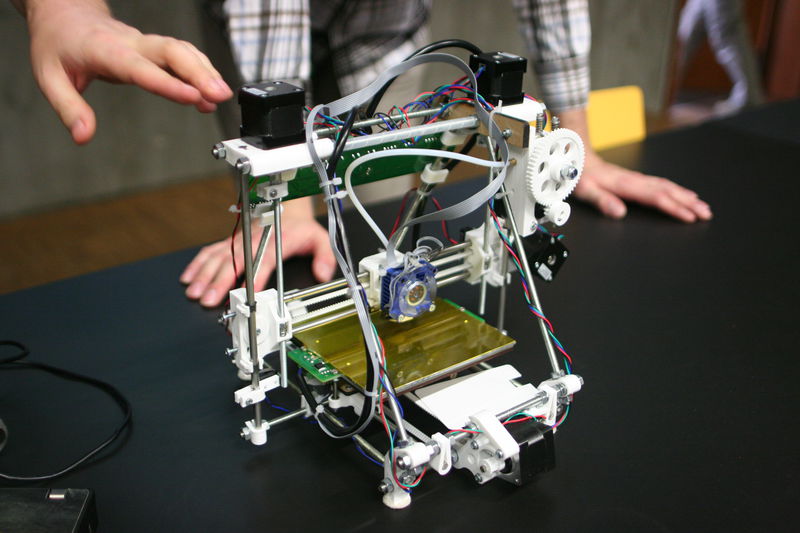

RepRap is a project that was created as a reaction to the expired patent on printing using thermoplastic extrusion. Adrian Bowyer (University of Bath) founded the project in 2005 with the goal of creating a 3D printer that anyone can build themselves from parts printed on a 3D printer and commonly available mechanical parts.

In 2006, the first proprietary component was successfully printed and soon after the first printer and its copy were created.

More at reprap.org/wiki/RepRap_history.

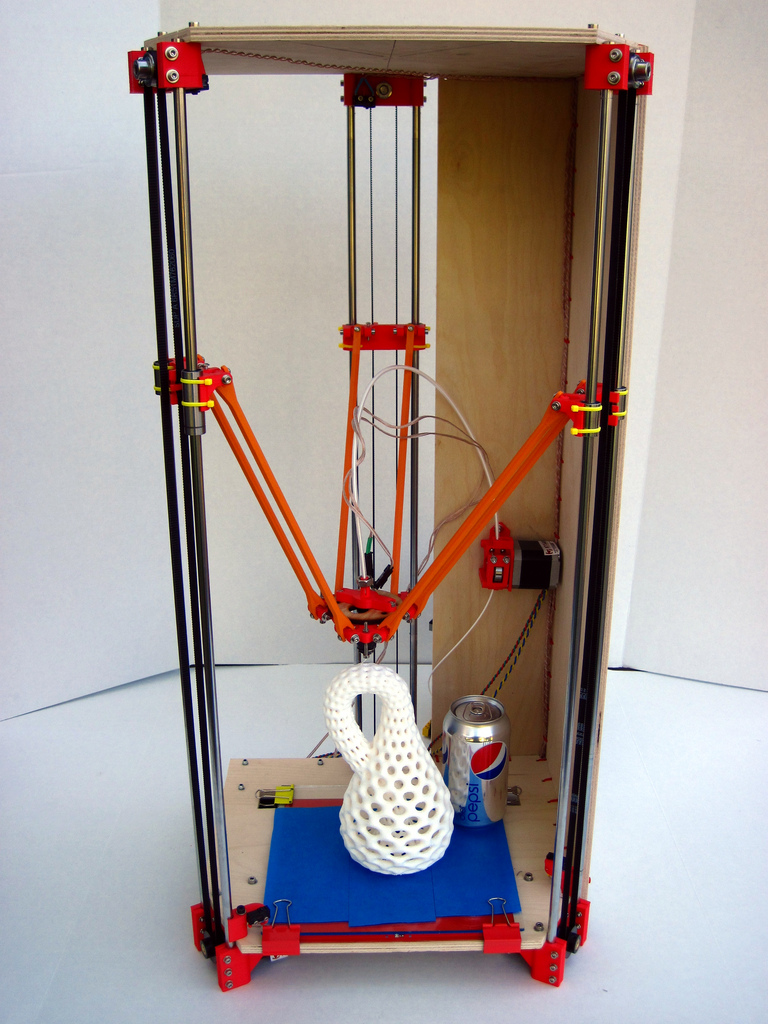

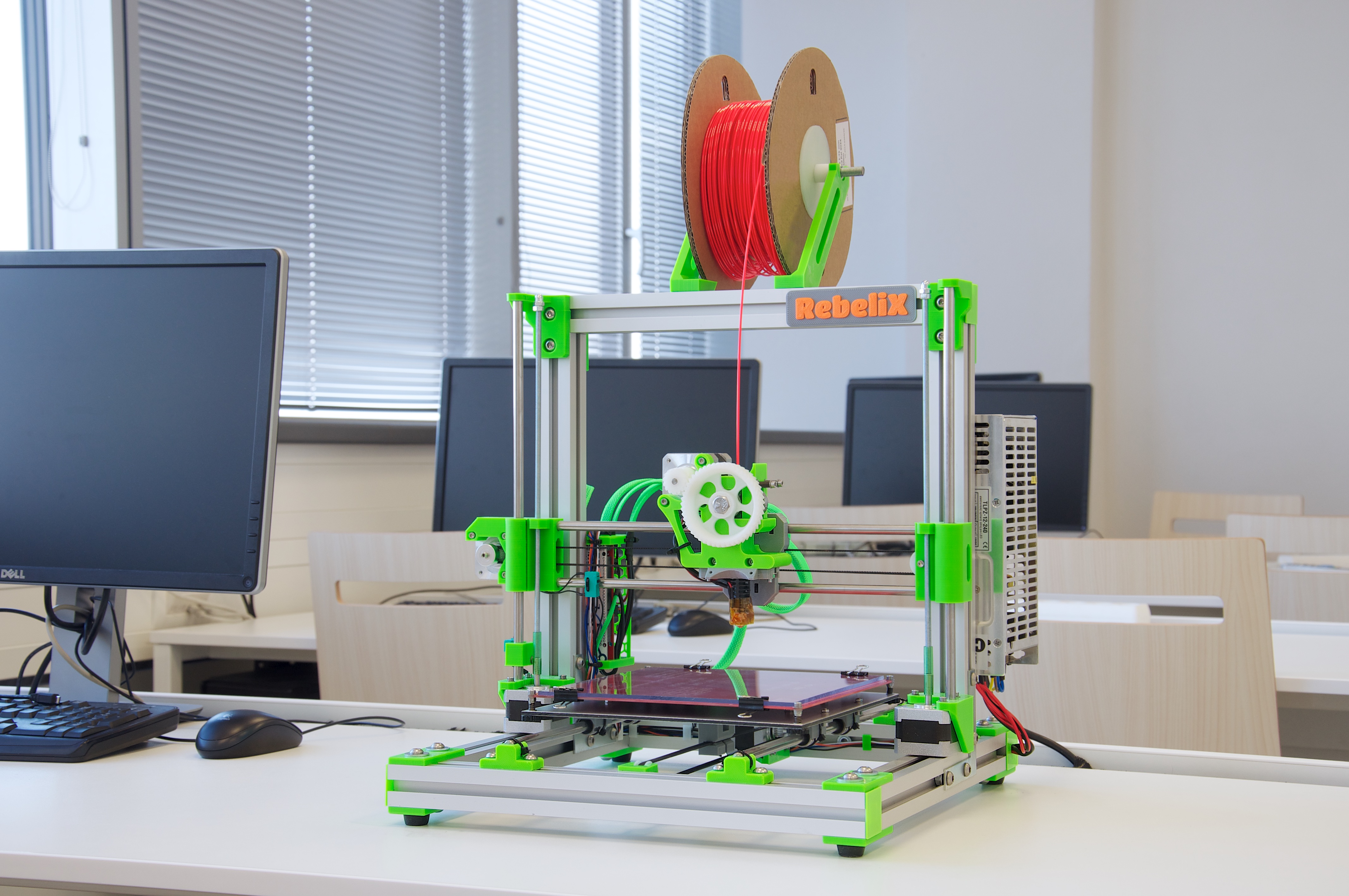

The RepRap project has since grown into a worldwide phenomenon that revolves around open-source printers, mostly FDM-based, but free printers of other technologies exist as well.

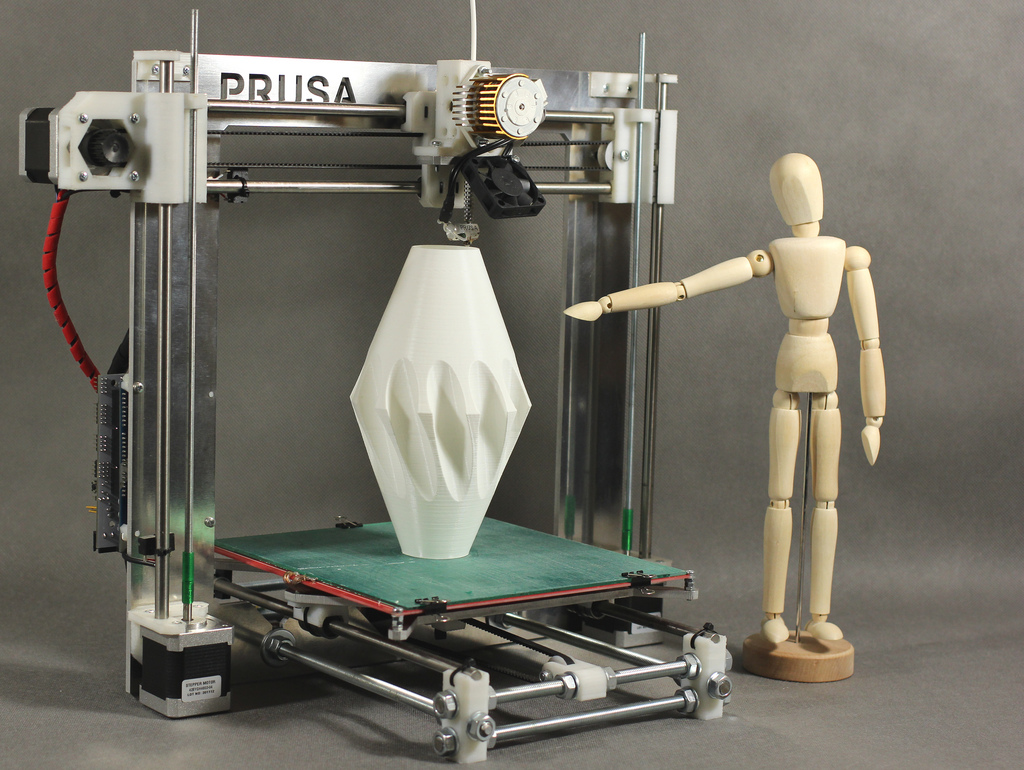

Probably the best-known open-source 3D printers today are those from the Czech company Prusa Research.

You can build your own printer today for less than 10 thousand crowns; there are low-cost variants that are even cheaper.

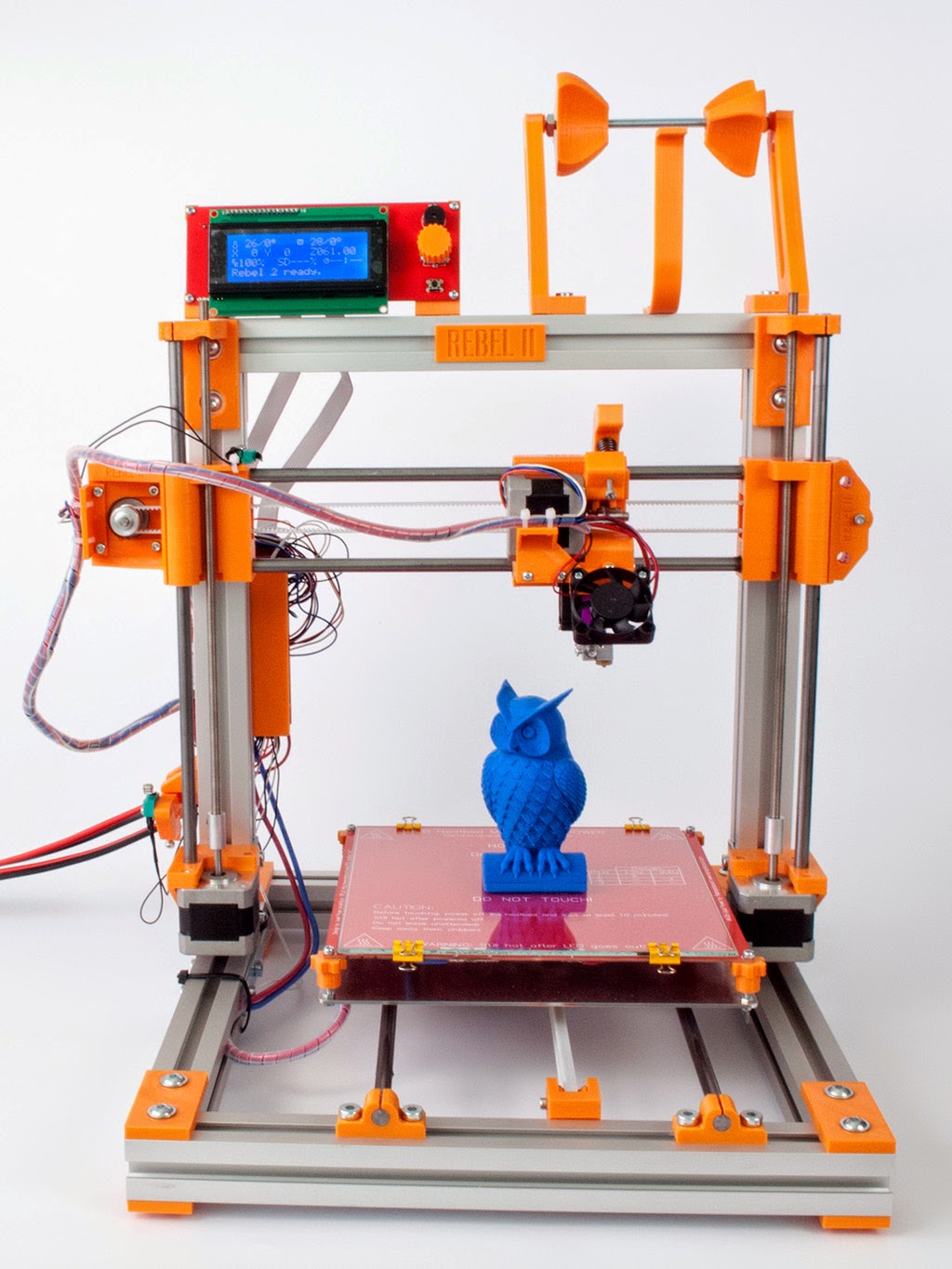

RepRap Models

In the true sense of the word, only those printers are RepRap that were created under the leadership of Adrian Bowyer at the University of Bath. In the broader sense, it’s any printer licensed under a GPL-compatible license that can print some of its own parts.

More models can be found on RepRap wiki.

Print Materials for FDM

Printers print from plastic wire, usually in the form of a spool. Most commonly used are:

- ABS

- Acrylonitrile butadiene styrene. You know it, for example, from LEGO® bricks. We’ll use it in the course because it’s sufficiently widespread, but at the same time printing from it is not trivial, due to strong thermal expansion. It has good properties after printing (durability, workability).

- PLA

- Polylactic acid. Biodegradable polyester product from plant materials. Very easy to print, but doesn’t withstand much, has a very low temperature at which it starts to soften, which complicates, for example, cutting, sanding, etc.

- PETG

- Glycol-modified polyethylene terephthalate (PET). The goal is to combine good printing properties of PLA and good properties of ABS prints.

More materials can be found on RepRap wiki.